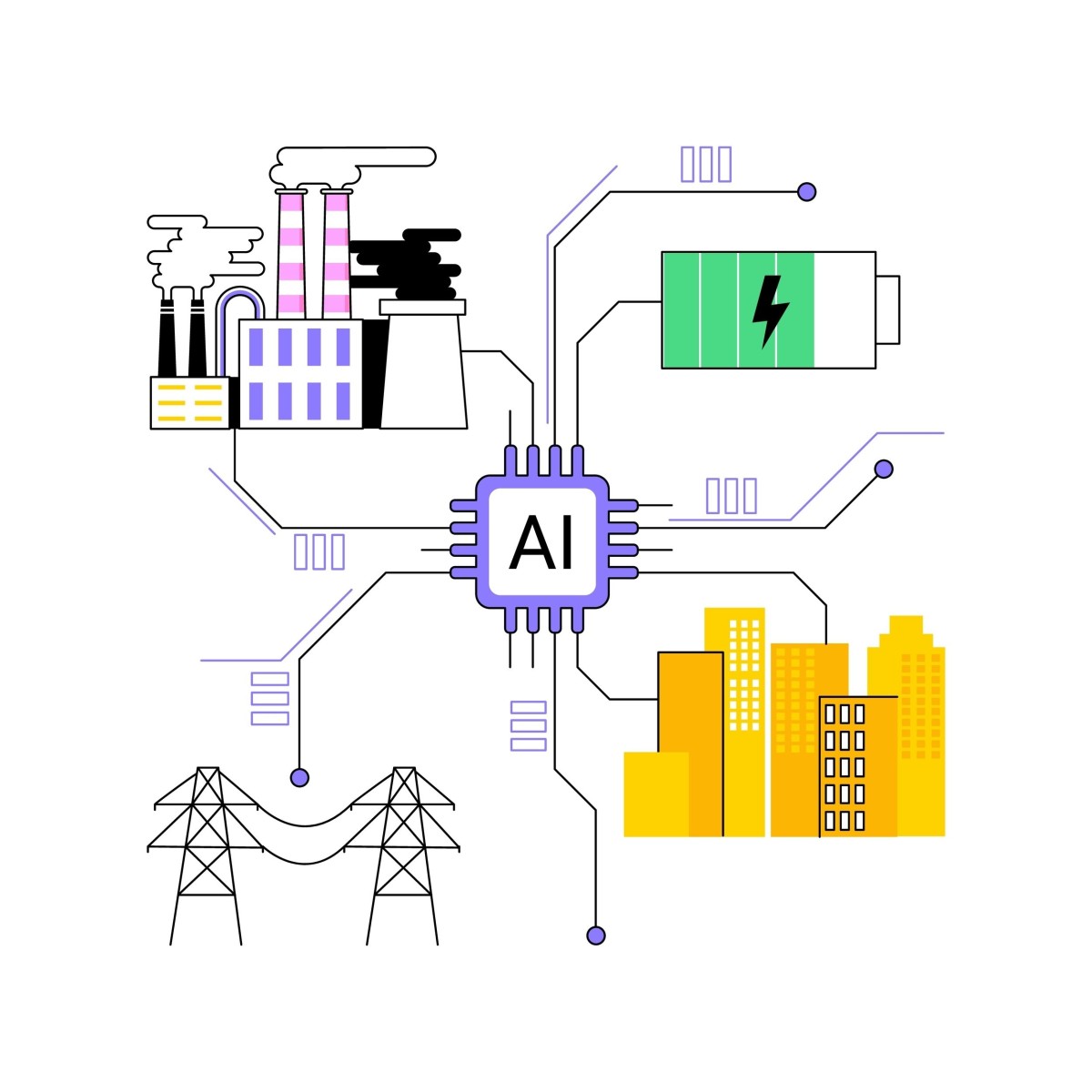

Artificial intelligence (AI)-enabled predictive maintenance could be a core component in the hunt for increased reliability and cost effectiveness. The integration of AI facilitates enhanced equipment upkeep predictability, better resource allocation, and overall plant efficiency improvement.

According to GlobalData, predictive maintenance could lead to a 30% reduction in maintenance expenses and a 20% enhancement in equipment availability. AI is central to innovations in maintaining electrical infrastructure, combining data analytics, machine learning, and real-time monitoring for accurate equipment condition predictions.

Rehaan Shiledar, Power Analyst at GlobalData, remarked: “Wind turbines and solar panels are frequently situated in remote or harsh environments, which can make repairs both challenging and costly. Predictive maintenance is playing a crucial role in ensuring these systems operate efficiently, thereby reducing the risk of unexpected breakdowns and the associated expenses.”

Organizations such as E.ON and Enel have implemented sensors on their turbines to track metrics like temperature, vibration, and wind speed, offering precise data collection for improved turbine performance and maintenance. RWE and Enel Green Power are pioneers in leveraging diagnostics software and condition monitoring for renewable energy sources like wind turbines and photovoltaic panels.

Predictive maintenance is gaining traction in energy storage systems, crucial for power grid stability and renewable energy integration. Enel Green Power partners with Volytica Diagnostics, a leader in battery diagnostics, to enhance battery systems' efficiency and safety.

Technology plays a pivotal role in predictive maintenance, with advancements in digital twin technology, the Internet of Things (IoT), and edge computing contributing significantly. The European Commission's Horizon Europe program launched a new initiative called TwinEU, spearheading digital twin development of Europe's electricity system, replicating energy systems for better management.

Companies such as Montel Energy utilize IoT (internet of things) based sensors for real-time monitoring of energy assets like transformers. Edge computing enhances this by enabling data processing at the data generation source, with companies like Microsoft and ABB integrating real-time analytics and automation into workflows.

Predictive maintenance is not only advancing the power market's digital transition but is also instrumental in enhancing sustainability. It supports operational excellence by helping manage assets in an environmentally responsible manner, aligning with the growing focus on sustainable practices in the industry. It's adoption is predicted to rise as its capacity to nurture business success is realised.